TPE: HEATED SAMPLE TRANSPORT TUBES – TRACEPAK® / STACKPAK™

Produce International

08/12/2024

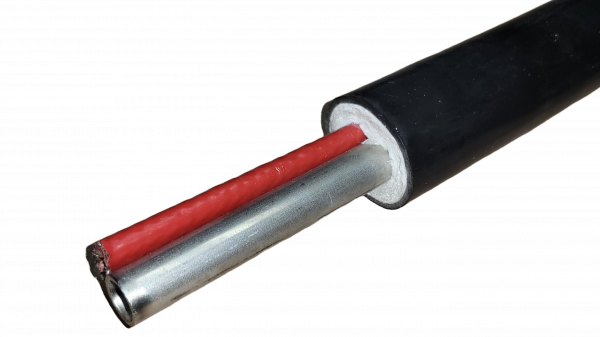

TPE systems provide a technologically advanced solution for transporting and preserving analytical samples in complex industrial environments.

Designed to deliver high performance in critical conditions, TRACEPAK® and STACKPAK™ heated tubes are essential for maintaining the quality and integrity of samples during transfer.

TRACEPAK® and STACKPAK™ by O’Brien: Advanced Sample Transport Systems for Industry

TRACEPAK® is a system designed for general process applications, offering protection against freezing, temperature maintenance, and viscosity control. It is ideal for transporting samples in process environments where maintaining stable performance over long tubing runs is crucial.

STACKPAK™, on the other hand, is specifically designed for exhaust gas, environmental, and process monitoring.

In particular, STACKPAK™ ensures uniform temperature maintenance for gaseous samples such as NOx, SOx, and CO2, while also providing antifreeze protection for liquid samples. It is highly customizable, allowing for the selection of various process tubes and configurations, including the integration of power and signal wiring, as well as pre-installed temperature sensors for precise control.

Why Choose TPE Systems?

TRACEPAK® and STACKPAK™ heated tubes offer numerous advantages, including:

- → High-Quality Materials: Each bundle is constructed with chlorine-free urethane jackets, non-hygroscopic insulation, and optional fluoropolymer jackets for enhanced chemical resistance and durability.

- → Temperature Maintenance: With integrated heating technology, high-temperature tubes ensure optimal thermal stability, reducing the risk of sample alteration.

- → Extreme Condition Resistance: Built with high-performance materials, heated stainless steel tubes can operate in environments with high temperatures and pressures, guaranteeing reliability and longevity.

- → Flexibility and Easy Installation: The TRACEPAK® and STACKPAK™ range includes flexible heated tubes, heated hydraulic tubes, and high-pressure heated tubes, designed to adapt to complex configurations, simplifying installation and maintenance.

- → Application Versatility: Ideal for precision applications, chemical analysis, environmental monitoring, and industrial processes.

- → Global Compliance: The system is certified for use in hazardous areas, adhering to global safety and performance standards.

- → Customization: Available in a wide range of configurations and options, including seamless stainless steel tubes, Duplex, Super Duplex, and special alloys such as Monel nickel and titanium, to meet specific application requirements.

Applications of TPE Systems

TRACEPAK® and STACKPAK™ heated tubes are employed across various industrial sectors:

- → Oil & Gas: Analysis of fluids, gases, and vapors in offshore and onshore environments.

- → Chemical Industry: Transportation of temperature-sensitive samples for quality control and process monitoring.

- → Environmental Monitoring: Sampling of atmospheric and industrial gases.

- → Complex Industrial Processes: In production plants.

For more information about TRACEPAK® and STACKPAK™ heated tubes, do not hesitate to contact us.

Hai qualche domanda?

Fornitori materiale meccanico, elettrostrumentale ed elettrico per impianti industriali del settore chimico e petrolchimico e dei settori energetici