SEAMLESS TUBES: THE OPTIMAL SOLUTION FOR THE MECHANICAL INDUSTRY

Produce International

07/12/2024

Seamless tubes are an essential choice for the mechanical industry due to their reliability, precision, and durability. Manufactured without joints, these seamless tubes ensure excellent performance in applications that require maximum safety.

Historically considered an advanced solution for sectors such as oil & gas, chemical, and petrochemical, seamless steel tubes stand out for their ability to withstand high pressures, thermal fluctuations, and aggressive environments.

The seamless manufacturing process results in products with uniform metallurgical characteristics, eliminating the potential weak points typical of traditional joints.

Advantages of Seamless Tubes for Mechanical Applications

Seamless mechanical tubes offer a series of benefits that make them ideal for a wide range of applications, such as:

- → High Structural Strength: The absence of welds eliminates weak points, ensuring greater integrity and longer lifespan.

- → Precise Tolerances: Perfect for high-precision applications, such as in mechanical processing or advanced industrial processes.

- → Material Versatility: Available in a wide range of materials, including carbon steels, stainless steel tubes, and special alloys such as nickel alloys or duplex and super duplex tubes.

- → Performance in Critical Environments: Ideal for high-pressure applications, extreme temperatures, and corrosive environments, such as those typical in the petrochemical industry.

Industrial Applications: Sectors Where Seamless Tubes Make a Difference

Seamless precision tubes are used across numerous industries thanks to their versatility and exceptional performance:

- → Oil & Gas: Used to transport fluids at high pressure, resistant to corrosion, and ensuring safety in extreme environments.

- → Chemical and Petrochemical Industries: Perfect for complex plants where it is crucial to avoid leaks or malfunctions due to defective welds.

- → Mechanical Engineering: Used in hydraulic systems, cylinders, and other applications requiring maximum precision and reliability.

- → Shipbuilding and Aerospace: Stainless steel tubes and special alloys ensure optimal performance even in extreme conditions.

Regulations and Certifications: A Quality Standard

To ensure safety and reliability, seamless tubes are manufactured according to strict international standards, such as ASTM, NACE, and PED regulations. These standards ensure that the tubes meet the technical specifications required for various industrial applications, adhering to safety and quality regulations.

Why Choose Seamless Tubes from Produce International?

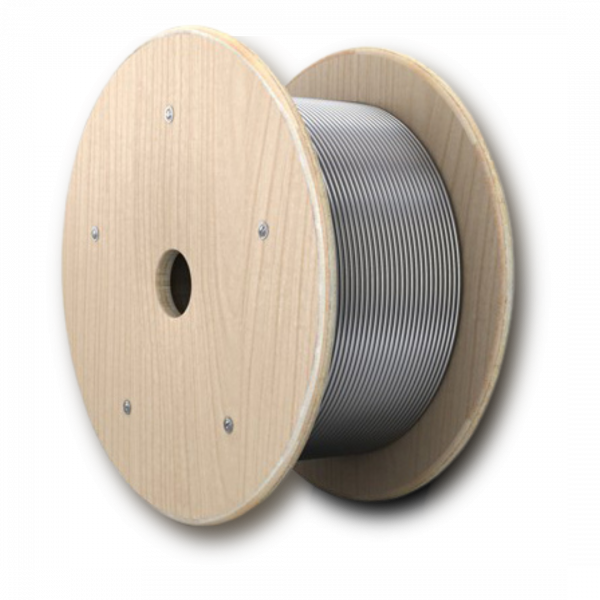

We offer a wide range of high-quality coil tubes made from various materials sourced from the EU, the United States, South Korea, or Japan, with all types of specifications: ASTM, ASME, DIN, ISO, EN, NACE, PED, Norsok, AD 2000 W2, TÜV, and Lloyd’s Register.

Hai qualche domanda?

Fornitori materiale meccanico, elettrostrumentale ed elettrico per impianti industriali del settore chimico e petrolchimico e dei settori energetici